Today we’ll talk about the journey water takes before reaching our taps, along with the pros and cons of water treatment systems in Ukraine. Many people complain about water quality, but not everyone knows why the water is the way it is.

Where does water come from?

Water for centralized water supply systems can come from two main sources: surface water bodies and underground wells. Sometimes, a mixture of both is used. For example, Kyivvodokanal supplies different types of water—from the Dnipro, Desna rivers, and 363 underground wells. Meanwhile, the small town of Brovary in Kyiv region gets water only from underground sources.

Let’s explore the differences in the initial composition of these waters, along with their pros and cons.

Surface water

River or lake water often presents a number of specific challenges that need to be addressed:

- Turbidity, caused by silt from microorganisms, suspended clay particles, etc.

- Color and odor, mostly due to natural organic substances.

- Microbiological contamination with pathogenic microorganisms.

Depending on the region, water may also show elevated hardness, iron, heavy metals (industrial areas), nitrates, and pesticides (agricultural regions).

Groundwater

As for well water, it has entirely different issues. These include hardness, high levels of iron and/or manganese, and hydrogen sulfide. In some cases, specific contaminants may also be present. For instance, even deep artesian waters in eastern Ukraine—usually considered clean—can contain heavy metal ions.

Historically, underground water sources have been underused, even in places where they could supply enough volume. This dates back to Soviet times, when preference was given to building long pipelines instead of utilizing well water.

Thus, water treatment processes primarily depend on the source. The type and concentration of pollutants typically determine the dosage of reagents, settling times, and filtration modes.

Based on these common water quality issues, we can understand the logic behind water treatment system layouts. Let’s look at typical surface and groundwater treatment systems used in Ukraine.

Surface water treatment systems

In general, traditional systems in Ukraine are similar. We'll use the Dnipro Water Treatment Plant as an example. Built in 1939, its designed capacity is 600,000 m³/day, but it currently provides about a third of that—200,000 m³/day. It supplies water to districts like Obolon, Podil, Vynohradar, and parts of the ring road area.

Water is taken directly from the Dnipro River using intake scoops and a first-lift pumping station. The intake is located near Velykyi Island, at the junction of the Dnipro and Desna Rivers in Kyiv’s Obolon district.

River water intake

Special grates at the intake prevent large debris from entering the system. Additional features include ultrasonic emitters to repel fish and a ventilation system to divert oil slicks and large algae clusters.

Pumping stations

These stations pump water to the treatment facilities. The pumps are located underground, while the large, noisy engines are above ground. Although new pumps have been installed, some of the 1939 equipment can still operate. The main reason for replacing old pumps is their low energy efficiency.

These stations pump water to the treatment facilities. The pumps are located underground, while the large, noisy engines are above ground. Although new pumps have been installed, some of the 1939 equipment can still operate. The main reason for replacing old pumps is their low energy efficiency.

At the first lift stage, chlorine is added to disinfect the water, destroy some organic matter, and prevent biofouling in the treatment system tanks.

Mixing with reagents

Next, water flows into a mixing chamber where coagulants are added. These cause suspended particles to clump together via electrostatic attraction. The most commonly used coagulants are aluminum compounds (aluminum hydroxychloride and sulfate). Up to 40 tons of coagulants can be used per day. This is one reason aluminum levels in treated surface water may exceed safe limits.

Flocculants are also added—polyacrylates (30–40 kg/day) and silicic acid (up to 2 tons/day). These help form larger particles via polymer bridges rather than electrostatic means. This also helps remove natural organic substances like fulvic acids, which cause water discoloration.

These reactions cause tiny colloidal particles to stick together and settle faster due to increased weight.

Sedimentation

Water then moves into horizontal sedimentation tanks—essentially large rectangular basins. The Dnipro station has 9 of these, with their number based on the plant’s capacity and the size of each basin.

Filtration

Next comes rapid filtration. This involves tanks filled with sand that trap particles larger than 10–30 microns in the spaces between sand grains.

Ozonation

After that, the water goes through an ozonation stage in bubbling chambers. Here, water is infused with bubbles of oxygen and ozone. Ozone is a powerful oxidizer that breaks down organic molecules and microorganisms, clarifying and disinfecting the water.

This stage has been part of the Dnipro station since 1972, making it unique at the time. Although it’s more common today, it’s still not widespread.

Disinfection

Finally, the water enters a storage tank where it’s chlorinated again. Then, it’s pumped into the distribution system by the second-lift pumping station.

As of 2020, the Dnipro station was planning to switch from chlorinated water to chlorine dioxide disinfection, which will be generated onsite through electrolysis. This is currently the most effective and safest disinfectant. Unlike stored chlorine, it eliminates the risk of a potential industrial disaster in Kyiv.

It’s worth noting that both the Dnipro and Desna treatment plants have in-house laboratories conducting constant water quality monitoring—something not all towns can claim.

Well water purification systems

In some cities of Ukraine, well water is the primary or even the only source of drinking water, such as in Lviv or Kharkiv.

We have previously discussed the issues related to underground water — hardness, high levels of iron, manganese, and hydrogen sulfide.

In this case, the focus is on iron removal, not precipitation.

This process is also demonstrated in the water treatment system in the city of Slavuta, Khmelnytskyi region. The station was recently built but generally follows the traditional system, except for the full automation of the process.

In the city, there are 14 wells providing 12,000 m³ per day. The typical problem here is the high level of iron.

At the water treatment station, seven filters have been installed. These filters are columns filled with special material that filters the water, traditionally using clinoptilolite.

This material is a natural zeolite, extracted from the Zakarpattia region, significantly reducing the cost of water purification.

After that, the water is disinfected using sodium hypochlorite.

As you can see, underground water purification systems are much more compact and simpler.

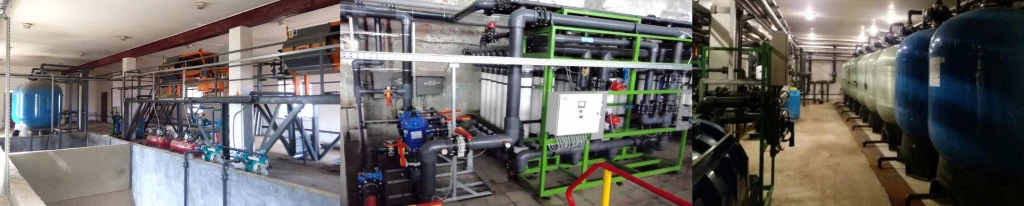

Implemented water utility projects by Ecosoft

Ecosoft manufactures and installs systems of any complexity, including water utility equipment. Below, we list some of the projects we have worked on.

Central water utility of Brusyliv, Zhytomyr region

In this case, a system with a capacity of 18 m³/hour was installed, which included:

Two parallel-installed Arkal 2" Dual mechanical filtration filters.

Iron removal system Ecosoft FPP + 2472 with six cylinders filled with Filter Ag+ material, which ensures the removal of mechanical particles.

Water utility of Kharlyk, Kyiv region

The station's capacity is 250 m³/day. The main issue was that underground water contained concentrations of iron and manganese that exceeded the MAC by 2.5 and 3 times, respectively.

The station consisted of a number of components:

A reservoir to supply the incoming water, which included a spraying system for partial oxidation of contaminants during the water intake.

Arkal 2" Dual mechanical filtration filters to remove clay, sand, and other particles.

A sodium hypochlorite dosing station for oxidizing iron and disinfecting the incoming water. The station is managed online.

Iron removal system based on Ferromix material, a unique development by Ecosoft specialists. The material ensures the removal of iron, manganese, and hydrogen sulfide in a single stage.

After purification, the water is delivered to a clean water reservoir.

All containers are made from food-grade plastic, tailored to the customer's size and specifications.

Water treatment system reconstruction in Izhevske, Kazakhstan

The task was to fully upgrade the water treatment station with a capacity of 2,000 m³/day.

The system includes:

Ozonation.

Reagent dosing.

Mechanical filtration using packed filters.

Ultrafiltration.

Disinfection with hypochlorite.

Sorption on activated carbon.

Pressing the sludge after membrane flushing.

It is worth noting that ultrafiltration is widely used in water treatment systems worldwide. This technology justifies itself with high-quality filtration, reduced equipment size, and high efficiency, regardless of the quality of the incoming water.

Why does dirty water come from the taps?

If the water goes through so many stages of purification, why does it still come out of the tap murky and with a yellowish tint? The reason is that after treatment at the water utility, it enters the pipeline system. The inner surface of the pipes is coated with various deposits and biological growths. The chlorine, which is dosed into the water for prolonged disinfection, oxidizes these substances, resulting in the release of byproducts into the water. In addition to giving the water undesirable organoleptic properties, these byproducts are carcinogenic.

Can you drink tap water?

In fact, the water supplied to the pipes by water utilities often meets state drinking water standards. It may contain a certain amount of toxicants, but it generally won't pose a serious health risk. However, there are also unscrupulous water utilities and old water pipes that pollute the water on its way to your tap.